Inventory Management Software Unlocks Efficiency and Profitability for Businesses

Our generation is witnessing a digital revolution. With continuous innovation and research, it has taken center stage in the business realm. With the application of sophisticated technological solutions, managing business has become easier than ever before.

However, supply chain management is the primary concern of businesses nowadays due to past events, i.e., the COVID-19 outbreak and geopolitical instability.

Thus, we need a sound solution to prevent such situations from hampering business. Apart from that, businesses also want to lower their input costs and improve their profitability. To cater to the needs of businesses, we need a modern inventory management process.

In this blog, we will discuss modern inventory management systems and techniques for the best utilization of resources and increasing profitability.

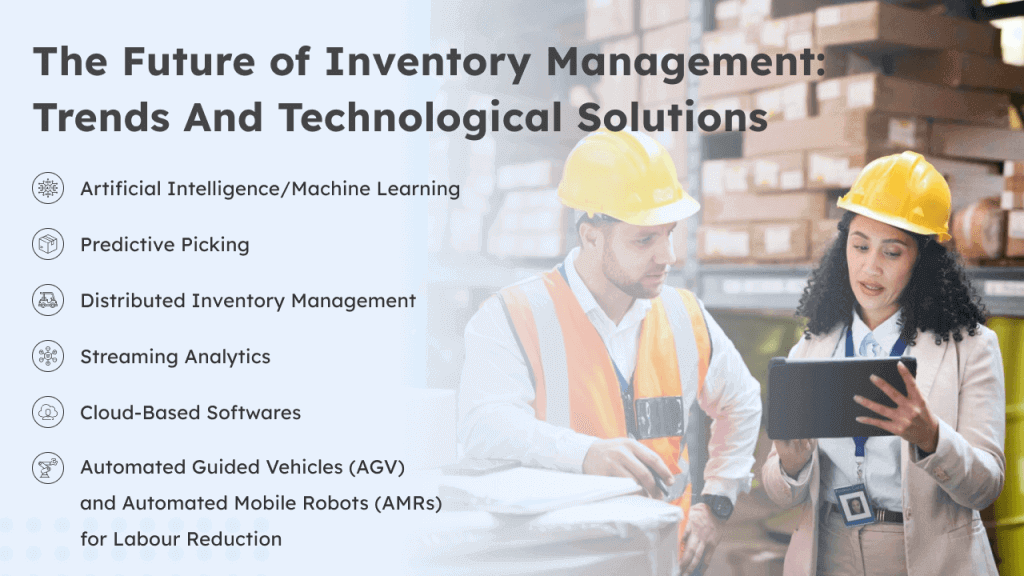

The Future of Inventory Management: Trends And Technological Solutions

Following are the cutting-edge trends and technologies for managing inventory more effectively:

Application of Artificial Intelligence/Machine Learning

The future of warehouses will be integrated with sophisticated AI and machine learning algorithms. These algorithms will utilize unstructured data from spreadsheets to understand customer buying behavior, stock inflow patterns, and other interdependent factors. All the data will be processed together, and the output will be a prediction.

Apart from data predictions, AI and ML will be employed in material handling systems via robots. These robots will not require navigational inputs from outside; they will make a map of your warehouse and move accordingly.

Predictive Picking

Just like artificial intelligence tools, predictive picking relies primarily on data analysis to predict patterns in demand surges. The purpose of predictive picking tools would be to initiate fulfilments before receiving an order. The accuracy of predictions is dependent on the data being fed to the system. The application of such systems results in shorter lead times and enhances the customer experience.

Distributed Inventory Management

Under a distributed inventory management system, inventories are stocked at multiple different locations across a particular region, a country, or the world. Storing stocks across multiple locations results in more efficient supply chain management and faster deliveries.

This method of inventory management could be a boon for businesses in case of a war, natural calamities, COVID-19-like pandemic situations, and much more.

Amazon and other super-giant e-commerce companies have already adopted this method of inventory management, which is why they are successful at product fulfillment.

We are now addressing your main concern: management. In the multi-warehousing model, inventory management will be done using cloud-based software. We will discuss the same in detail shortly.

Streaming Analytics

The world is changing rapidly, and so is the method of decision-making in business. Earlier, managers relied on weekly, month-end, or quarterly data to make critical decisions for the company, but this method is obsolete in this ever-changing world. Due to customer-centricity and the popularity of personalization, businesses should make use of ‘streaming analytics’.

As the name suggests, it streams real-time data to users so that they can make informed decisions. This approach provides relatively real-time data to users so that they can make informed decisions.

This is relatively new, but we mentioned it because it is relevant to businesses of the new age. This approach enables demand forecasting, replenishing inventory, preventing stock-outs, staying updated with real-time information on goods in supply, determining vendors’ performance with real-time data, and understanding how and what factors lead to price change.

Cloud-Based Softwares

Cloud technology is a boon for managers and businessmen. It allows you to manage and track your business from anywhere in the world and also indirectly improves the efficiency of your business processes. Cloud technology enables you to sync across warehouses and stores situated in different locations and processes information from procurement and other data channels across the supply chain.

Cloud-based inventory management software has facilitated employees’ ability to work from anywhere, leading to better productivity and work-life balance.

Benefits of cloud technology in the inventory management process:

- Sync data across various departments

- Serves as a central repository for business data

- Can be scaled up or down anytime as per the requirement

- Employees across the organization can make use of tools that easily integrate with third-party applications

- Works with modest hardware

Automated Guided Vehicles (AGV) and Automated Mobile Robots (AMRs) for Labour Reduction

In a competitive environment, it would be good for your company to provide the best customer experience by providing on-time delivery. To do so, your fulfillment process should be more efficient. Automated guided vehicles (AGVs) and automated mobile robots (AMRs) are tools to decrease lead time and increase productivity. These robots assist in warehouse operations by picking or collecting products from the given pallets and decks.

Let’s understand how they work in brief.

AGV has magnetic strips to trace a fixed path provided through the warehouse. Thus, they aren’t suitable for facilities that change the floorplan or have a lot of obstructions.

While AMRs are a newer technology, they can navigate across the warehouse and are not restricted to the fixed route as they are equipped with smart sensors.

Both robots reduce the time taken to move products within the warehouse. You should invest in this technology if you are dealing in heavy-weight products.

Over to You

So these are the modern technologies to make the inventory management process more efficient and effective. We hope that after reading this blog, you will understand the significance of cutting-edge inventory management techniques. In any case, if you are looking for a complete business solution that provides accounting, invoicing, and inventory management features in one software, then you must try Munim, India’s leading accounting software.

Frequently Asked Questions on Inventory Management Techniques

- What are the four inventory management techniques?

Here is a list of four major inventory management techniques that are widely used in industries:

- Just-in-time (JIT)

- Economic order quantity (EOQ)

- Materials requirement planning (MRP)

- Days sales of inventory (DSI)

- What is the future of inventory management and control?

The future of inventory management and control will come with a solution to mitigate supply chain disruptions with the application of artificial intelligence, machine learning, the Internet of Things, and data analytics.

- What are the technologies in inventory management?

Here is a list of technologies in inventory management:

- RFID tags

- Machine learning

- Automated picking tools

- Warehouse management software

- Barcode system

- Internet of Things

- LiFi technology

- Artificial intelligence

- How to improve inventory management using AI

The application of AI in inventory management helps automate the storage, collection, and dissemination of all inventory-related data.